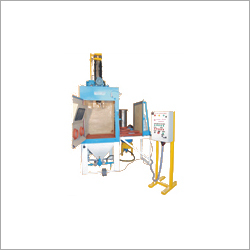

Shot Peening Machine

Shot Peening Machine Specification

- Material

- Stainless Steel / Alloy Steel

- Processing Type

- Automatic / Semi-Automatic

- Condition

- New

- Technology

- Air Blasting / Centrifugal Wheel

- Dimension (L*W*H)

- Customized / As per Model

- Power Mode

- Electric

- Voltage

- 380V / 415V

- Power Consumption

- 5 - 15 kW (depending on model)

- Engine Configuration

- Electric Motor Driven

- Application

- Metal Surface Finishing, Stress Relieving, Automotive Parts, Aerospace Components, Springs, Gears

- Weight

- Varies by Model (typically 800 kg - 2000 kg)

- Coating Type

- Nozzle Protected / Abrasion Resistant

- Chamber Material

- Wear Resistant Alloy Plates

- Surface Roughness Achievable

- Ra 2.0 6.3 m

- Dust Collector

- Cartridge / Bag Filter Type

- Blasting Nozzle

- Tungsten Carbide (Replaceable)

- Control Panel

- PLC Controlled

- Max Workpiece Size

- Upto 2000 x 1500 mm (customizable)

- Maintenance

- Low, with Easy Access Panels

- Safety Features

- Interlocking Doors, Overload Protection, Emergency Stop

- Noise Level

- < 80 dB (with Enclosure)

- Abrasive Used

- Steel Shot / Cut Wire / Glass Beads

- Shot Flow Rate

- 60 - 250 kg/min

- Conveyor Type

- Belt / Roller / Rotary Table (as per application)

Shot Peening Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 8 Pieces Per Week

- Delivery Time

- 4-6 Week

About Shot Peening Machine

Being well-equipped with the latest technology machinery & equipment and supported by a team of professionals, we are engaged in manufacturing and supplying Special Purpose Cabinet. This cabinet is used for shot blasting application in metallurgical industry. To comply with set industrial norms we use finest quality mild steel and cast iron to manufacture this cabinet. Available in different technical specifications, this Special Purpose Cabinet is highly demanded among clients.

Features:

- Rugged construction

- Easy installation

- Requires less maintenance

Advanced Control & Flexibility

The machines PLC-controlled automation ensures consistent, precise peening for different component profiles. Based on application needs, you can choose from belt, roller, or rotary table conveyors, and select between air blasting or centrifugal wheel technology. This flexibility makes it ideal for processing springs, gears, and specialty aerospace or automotive parts.

Built for Durability and Safety

Manufactured from stainless steel and wear-resistant alloys, the chamber is designed for longevityeven in demanding environments. Safety is enhanced with interlocking doors, overload protection, and emergency stop features. Easy-access panels and low-maintenance requirements simplify routine checks and servicing, ensuring continuous operation.

Efficient Dust & Noise Management

A built-in dust collectoravailable in cartridge or bag filter typesensures a clean working atmosphere by effectively trapping particulates. The machine enclosure helps maintain noise levels below 80 dB, creating a comfortable and compliant workspace for operators.

FAQs of Shot Peening Machine:

Q: How does the shot peening process in this machine improve metal components?

A: Shot peening introduces controlled compressive stresses onto the surfaces of metal parts using abrasives like steel shots or glass beads. This process increases fatigue strength, enhances resistance to stress corrosion, and extends the service life of critical components such as gears, springs, and aerospace parts.Q: What materials and workpiece sizes can the machine handle efficiently?

A: The machine supports workpieces up to 2000 x 1500 mm, with custom dimensions available for special requirements. It is suitable for a variety of ferrous and non-ferrous metals commonly used in automotive, aerospace, and general manufacturing.Q: When should I select air blasting versus centrifugal wheel technology?

A: Air blasting is optimal for delicate or intricate components, providing precise control, while centrifugal wheel technology is more effective for processing larger batches or heavy-duty parts, offering higher throughput and efficiency.Q: Where is dust and spent abrasive collected during operation?

A: All dust and spent abrasives are efficiently captured by an integrated dust collector unit, which is available in cartridge or bag filter options. This maintains workplace cleanliness and environmental compliance.Q: What is the maintenance routine and how accessible are service points?

A: Maintenance is simplified by the machines low-maintenance design and easy-access panels. Routine checks typically involve nozzle inspection and filter replacement, all of which can be conducted quickly to minimize downtime.Q: What safety mechanisms are in place to protect operators?

A: Key safety features include interlocking doors that prevent operation when open, overload protection to safeguard electrical components, and emergency stop switches for instant shutdown in case of emergencies.Q: What are the main benefits of using this shot peening machine for manufacturers?

A: Manufacturers benefit from improved component durability, consistent surface roughness (Ra 2.0 6.3 m), reduced risk of operational hazards, and streamlined production thanks to customizable automation and effective dust and noise management features.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Custom Built Equipments Category

Belt Tumbler Blasting Machine

Price Range 350000.00 - 550000.00 INR / Plant

Minimum Order Quantity : 1 Plant

Condition : New

Processing Type : Customized

Material : IS 2062

Id Cleaning Blasting Machine

Price 350000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Processing Type : Customized

Material : IS 2062

Pneumatic Tumblast Blasting Machine

Price 350000-600000 INR / Number

Minimum Order Quantity : 1 Number

Condition : New

Processing Type : Standard

Material : Batch Cleaning

Roll Etching shot blasting Machine

Price 750000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Processing Type : Customized

Material : Steel

GST : 08AAPPG4490H1ZE

|

KUSHAL UDHYOG

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry