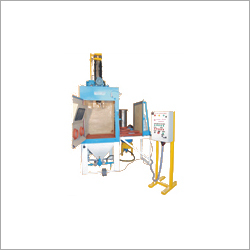

Roll Etching shot blasting Machine

Price 750000.00 INR/ Unit

Roll Etching shot blasting Machine Specification

- Material

- Steel

- Processing Type

- Customized

- Condition

- New

- Power Mode

- Pneumatic

- Voltage

- 440 Volt (v)

- Power Consumption

- 10 Horsepower (HP)

- Application

- Shot Blasting

- Weight

- 1000 Kilograms (kg)

Roll Etching shot blasting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Thar Dry Port

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 8 Units Per Year

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Poly Pack

- Main Export Market(s)

- Asia, Eastern Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ZED SILVER

About Roll Etching shot blasting Machine

Roll Etching Machine

To establish a prominent presence in the market we are engaged in manufacturing and supplying Roll Etching Machine. This machine is manufactured in compliance with set industrial norms using best quality mild steel and cast iron. Highly demanded in the market, this machine is available in different technical and power specifications. We check this Roll Etching Machine on defined quality parameters to provide the defect free range to clients.

Key Features:

- Rugged construction

- Easy to operate

- Noise free performance

Efficient Surface Treatment for Steel Rolls

This shot blasting machine streamlines the etching process by effectively removing surface contaminants and preparing steel rolls for further treatment. Customization options enable adaptation to diverse industrial needs, ensuring that every batch of rolls meets quality and finish standards.

Robust Build and Superior Performance

Constructed from high-grade steel, the machine ensures reliability and a long service life, even in demanding environments. Its pneumatic power mode and 440 Volt operation deliver strong, consistent performance, making it a versatile asset for industrial operations.

FAQs of Roll Etching shot blasting Machine:

Q: How does the Roll Etching Shot Blasting Machine operate?

A: The machine utilizes a pneumatic power mode, powered by a 440 Volt electrical supply. It projects abrasive materials at high velocity to clean and etch the surfaces of steel rolls, ensuring thorough removal of contaminants and optimal surface preparation.Q: What is the main application of this shot blasting machine?

A: This equipment is primarily designed for the shot blasting and etching of steel rolls. It is ideal for preparing surfaces prior to coating, painting, or further processing in various industrial sectors.Q: When should the shot blasting process be used in manufacturing?

A: Shot blasting is typically performed before applying surface treatments such as painting, coating, or plating. It ensures that the steel rolls are free from rust, scale, or other impurities, offering a clean base for further processing.Q: Where is the Roll Etching Shot Blasting Machine commonly used?

A: These machines are widely used in steel processing plants, roll manufacturing units, and by exporters and suppliers across India who require consistent surface quality for steel rolls.Q: What is the benefit of using a customized processing type for this machine?

A: Customized processing allows the machine to be adapted to specific industrial needs and roll dimensions, resulting in better productivity, improved surface finish, and optimized integration into existing workflows.Q: How is the machine maintained for optimal performance?

A: Regular inspection and cleaning of abrasive components, periodic checking of pneumatic systems, and timely replacement of worn-out parts ensure the machine operates efficiently and has a long lifespan.Q: What advantages does this steel shot blasting machine offer manufacturers and traders?

A: It enhances productivity by increasing the speed and quality of surface preparation, reduces manual labor, and delivers consistent results, making it a valuable investment for exporters, suppliers, and manufacturers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Custom Built Equipments Category

Belt Tumbler Blasting Machine

Price Range 350000.00 - 550000.00 INR / Plant

Minimum Order Quantity : 1 Plant

Technology : Other

Condition : New

Material : IS 2062

Id Cleaning Blasting Machine

Price 350000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Technology : Other

Condition : New

Material : IS 2062

Pneumatic Tumblast Blasting Machine

Price 350000-600000 INR / Number

Minimum Order Quantity : 1 Number

Technology : Other

Condition : New

Material : Batch Cleaning

Shot Peening Machine

Price Range 250000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Technology : Other, Air Blasting / Centrifugal Wheel

Condition : New

Material : Stainless Steel / Alloy Steel

GST : 08AAPPG4490H1ZE

|

KUSHAL UDHYOG

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry