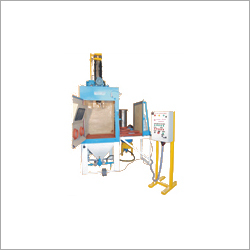

Grit Blasting Machine

Grit Blasting Machine Specification

- Material

- Mild Steel

- Processing Type

- Surface Preparation

- Condition

- New

- Technology

- Grit Blasting

- Dimension (L*W*H)

- 1420 x 910 x 1810 mm

- Power Mode

- Electric

- Voltage

- 415 V AC

- Power Consumption

- 7.5 KW

- Application

- Cleaning, Surface Treatment, Rust Removal, Paint Removal

- Weight

- Approx. 675 kg

- Coating Type

- Powder Coated

- WorkingSpeed

- Adjustable, up to 8 m/min

- Max Workpiece Size

- 1000 x 600 x 400 mm

- Noise Level

- 85 dB

- Machine Finish

- Industrial Paint

- Frequency

- 50 Hz

- Abrasive Hopper Capacity

- 220 kg

- Control Panel

- Automatic PLC

- Blast Wheel Quantity

- 2

- Operating Temperature Range

- 0C ~ 50C

- Blast Wheel Power

- 7.5 KW each

- Dust Collector Type

- Cartridge Filter

- Safety Features

- Emergency Stop, Overload Protection

Grit Blasting Machine Trade Information

- Minimum Order Quantity

- 1 Number, ,

- Supply Ability

- 8 Per Week

- Delivery Time

- 4-6 Week

About Grit Blasting Machine

grit Blasting Machine

We are one of the best manufacturer and supplier of industrial grade Blasting Machine which is highly efficient in operation. It is equipped with top quality electrical and pneumatic drives for the smoother operation. The frame of the machining cabinet is fabricated by using best quality engineering grade materials which makes it highly durable and rigid to withstand impact forces. It is also provided with an electrical control panel fixed with the machine frame to control the operational parameters.

Specification

| Production Capacity | 6-8 Per Year |

| Automatic Grade | Automatic |

| Motor Speed | VFD |

| Model Name/Number | KUS-SB4; KUS-SB6; KUP-SP2 |

| Driven Type | Compressed Air |

| Automation Grade | Automatic |

| Media | Aluminum Oxide |

| Brand | KU |

Efficient Surface Preparation

Optimized for surface cleaning, rust and paint removal, this grit blasting machine is a perfect choice for industrial applications. Its robust twin blast wheel system ensures uniform abrasive impact on workpieces of various sizes within a safe and controlled environment, aided by advanced PLC-based automation.

Advanced Safety and Dust Control

Prioritizing operator safety, the machine features emergency stop and overload protection systems. The cartridge filter dust collector dramatically reduces airborne dust, ensuring regulatory compliance and workforce well-being, while the durable industrial finish enhances machine longevity.

User-Friendly, Precise Operation

Engineered with an automatic PLC control panel, the system delivers intuitive adjustments to working speed and other settings. The design supports smooth operations and quick process changes, boosting productivity for exporters, manufacturers, traders, and suppliers in India's surface treatment industry.

FAQ's of Grit Blasting Machine:

Q: How does the automatic PLC control panel improve operation of the grit blasting machine?

A: The automatic PLC control panel allows for precise adjustments and automation of blasting cycles, enabling consistent operation and reducing manual intervention. This increases efficiency, eases operation, and enhances the accuracy of surface preparation processes.Q: What types of applications is this grit blasting machine best suited for?

A: This machine excels in cleaning, surface treatment, rust removal, and paint removal of workpieces up to 1000 x 600 x 400 mm, making it ideal for metal fabrication, automotive, and manufacturing industries seeking high-quality surface preparation.Q: When should the cartridge filter in the dust collector be replaced or maintained?

A: The cartridge filter's maintenance schedule depends on operational frequency and dust load. Typically, regular inspections are recommended, and filters should be cleaned or replaced when a decrease in suction or visible dust is observed, ensuring optimal dust extraction performance.Q: Where can this grit blasting machine be installed, considering its size and power requirements?

A: With dimensions of 1420 x 910 x 1810 mm and a requirement for 415 V AC power supply, this machine is suited for industrial workshops, factories, or surface treatment plants with adequate floor space and a compatible electrical setup.Q: What is the process flow when using this machine for surface preparation?

A: The process involves placing the workpiece in the designated chamber, setting the desired speed via the control panel, and starting the machine. Abrasive material is propelled onto the workpiece by two blast wheels, cleaning and preparing the surface while the dust collector manages particulate removal.Q: How does the adjustable working speed benefit users during operation?

A: Adjustable working speeds of up to 8 m/min allow operators to fine-tune the process for different materials and surface conditions, ensuring optimal results and efficient throughput regardless of the workpiece type or required finish.Q: What safety features are in place to protect operators?

A: The machine includes an emergency stop mechanism and overload protection, which immediately halt operation in the event of an incident, providing a safer working environment and reducing the risk of equipment damage or injury.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Custom Built Equipments Category

Belt Tumbler Blasting Machine

Price Range 350000.00 - 550000.00 INR / Plant

Minimum Order Quantity : 1 Plant

Condition : New

Voltage : 440 Volt (v)

Processing Type : Customized

Id Cleaning Blasting Machine

Price 350000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Voltage : 440 Volt (v)

Processing Type : Customized

Pneumatic Tumblast Blasting Machine

Price 350000-600000 INR / Number

Minimum Order Quantity : 1 Number

Condition : New

Voltage : 440 Volt (v)

Processing Type : Standard

Roll Etching shot blasting Machine

Price 750000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Voltage : 440 Volt (v)

Processing Type : Customized

GST : 08AAPPG4490H1ZE

|

KUSHAL UDHYOG

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry