Sand Blasting Machine Spares

Price 100-10000 INR/ Number

Sand Blasting Machine Spares Specification

- Diameter

- As per part specification

- Shape

- Round / Rectangular / Custom as per design

- Product Type

- Sand Blasting Machine Spares

- General Use

- Replacement parts for sand blasting machines

- Material

- Mild Steel / Alloy Steel / Cast Iron

- Type

- Nozzle, Coupling, Holder, Clamp, Hose, Gasket, etc.

- Capacity

- Depends on application and specific spare part

- Weight (kg)

- Varies depending on part

- Computerized

- No

- Automatic

- No

- Touch Screen

- No

- Control System

- Manual

- Surface Treatment

- Polished, anti-corrosive coating

- QC System

- Inspected for quality and compatibility

- Tolerance

- High precision as per standard requirements

- Drawing

- Available upon request

- Dimension (L*W*H)

- Varies as per part design

- Feature

- High durability, rust resistance, superior finish

- Color

- Silver / Grey / Custom

- Service Life

- Long operational life under standard usage

- Operating Temperature

- Suitable for high and low temperature environments

- Packaging

- Secure packaging for transit safety

- Installation

- Easy to install and replace

- Compatibility

- Suitable for standard sand blasting machines

- OEM Service

- Available

- Resistance

- High resistance to abrasion and wear

- Application

- Industrial sand/grit blasting operations

- Standard

- Manufactured as per industry standards

Sand Blasting Machine Spares Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 10 Per Week

- Delivery Time

- 4-6 Week

About Sand Blasting Machine Spares

Sand Blasting Machine Spares

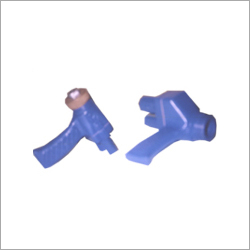

Kushal Udyog is a big name which deals in the manufacturing, supplying and exporting ofSand Blasting Machine Spares which is machined with the help of latest machining technologies that offers smoother finish and excellent dimensional accuracy which makes it very easier to install within the machining facility. The offered component part is especially designed for the centrifugal type shot blasting machineries and compatible with both dry as well as wet blasting techniques.

Used for holding 'straight' type nozzles in blasting cabinets. Two types of Sand Blasting Machine Spares are available, viz-Sand Blasting Machine Spares for dry blasting and Sand Blasting Machine Spares for wet blasting.

Exceptional Durability and Performance

Our sand blasting machine spares are crafted for rigorous industrial use, featuring high resistance to abrasion and wear. The anti-corrosive polished surfaces ensure reliable operation even in demanding environments. With precise tolerances and superior finish, these spares support optimal machine longevity and consistent blasting efficiency.

Versatile Compatibility and Customization

Suitable for a broad range of standard sand and grit blasting machines, each spare part is available in multiple shapes, dimensions, and material options. Custom dimensions, finishes, and colors are offered upon request, alongside OEM service, ensuring precise fit and ease of integration into existing systems.

Secure Packaging and Quality Assurance

Every spare is securely packed to prevent damages during transit and rigorously checked for quality and compatibility. With a comprehensive QC system, clients can be confident in receiving parts that meet stringent industry standards and align seamlessly with their sand blasting equipment requirements.

FAQs of Sand Blasting Machine Spares:

Q: How are sand blasting machine spares installed or replaced?

A: Sand blasting machine spares are engineered for straightforward installation and replacement. Most parts, such as nozzles, hoses, or gaskets, can be easily fitted using standard tools, minimizing machine downtime and ensuring continuous operation.Q: What compatibility do these spares offer with existing sand blasting machines?

A: These spares are compatible with most standard sand and grit blasting machines. Custom dimensions and OEM service are also available to ensure each part fits precisely with your specific equipment model and operational requirements.Q: When should I replace sand blasting machine spares in my equipment?

A: Replacement intervals depend on the intensity of usage, type of abrasive material, and operating conditions. Its advisable to inspect spares regularly and replace components once visible wear or reduced blasting efficiency is observed to maintain optimal performance.Q: Where can these spares be used within industrial operations?

A: Sand blasting machine spares are typically used across various industrial sectors, including manufacturing, construction, and maintenance, wherever surface preparation, cleaning, or finishing with abrasive blasting is required.Q: What is the process for ordering custom or OEM spares?

A: To order custom or OEM spares, simply provide your specific dimensions, drawing requirements, desired materials, and finish. The manufacturer or supplier will assist with prototyping and ensure the final parts meet your machines precise specifications.Q: What benefits do these spares offer over generic alternatives?

A: Our spares deliver high durability, rust resistance, and a superior polished finish, ensuring long operational life and reduced maintenance costs. Their adherence to strict industry standards guarantees reliability and compatibility for demanding industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Operated Type Grit Blasting Machines Category

Internal Pipe Blasting Tools

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other

Color : Orange & Black

Capacity : 12 m3/hr

Sand Blasting Machine

Price 105000.0 INR / Number

Minimum Order Quantity : 1 Number

Type : Other

Color : BLUE

Capacity : 500 Kg

Automatic Indexing Blasting Machine

Price Range 450000.00 - 900000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Rotary Indexing

Color : Industrial Blue/Custom

Capacity : 400800 kg per batch

Abrasive Blasting Machine

Price 500000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Type : Other

Color : Blue / Grey (custom colors available)

Capacity : Large chamber (customizable capacities available) Kg

GST : 08AAPPG4490H1ZE

|

KUSHAL UDHYOG

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry